Integrated passive devices are nothing new in our industry – they have been around for a long time and are well known.In fact,Analog Devices has produced such components for the market in the past.Careful design management of trace parasitics,device compatibility,and board assembly considerations is required when the chipset includes separate discrete passive components or integrated passive networks as part of it.While integrated passive devices continue to play an important role in the industry,their most important value can only be realized when they are integrated into system-in-package applications.

A few years ago,ADI began rolling out a new integrated passive technology program (iPassivesTM).Through this program,ADI aims to provide passive components such as diodes, resistors,inductors,and capacitors to cover signal chain design more broadly while overcoming the limitations and complexities of existing passive component methods.The need for a more complete solution with an efficient space size from ADI's customer base has also driven this program.From a designer's point of view,iPassives can be viewed as a flexible design tool that can design system solutions with best-in-class performance and robustness in a very short development cycle.ADI has a number of signal conditioning ICs,and our unique silicon manufacturing process enables these ICs to achieve superior performance.ADI can leverage the diversity of its existing products to produce plug-and-play systems with superior performance characteristics without the need to develop highly complex integration processes.Integrate passive technology with all of these existing technologies in a highly customizable network and package it with system-in-package technology to create fully certified,tested and characterized μModule® devices.Systems that previously used board-level solutions can now be simplified to a single device.From our customer's point of view,they now have a complete solution with outstanding out-of-the-box performance,reduced development cycles and cost savings,all in a very compact package.

Passive technology

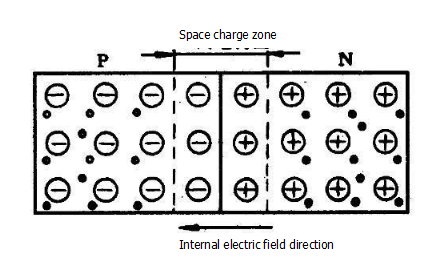

Now let's briefly review the basics and recall what passive components are. Passive components are devices that do not require a power supply, and their relationship between current and voltage is relatively simple. These components include resistors, capacitors, inductors, transformers (ie, effectively coupled inductors), and diodes. Sometimes the relationship between current and voltage is very simple, just as the current in a resistor varies linearly with voltage. For diodes, there is also a direct relationship between current and voltage, but this relationship is an exponential relationship. In inductance and capacitance, this relationship is the transient dependence of current on voltage. Table 1 shows the formula for defining these relationships for the four basic passive components:

Table 1. Basic formulas for the main passive components

Using integrated passive components in the micro-module SIP

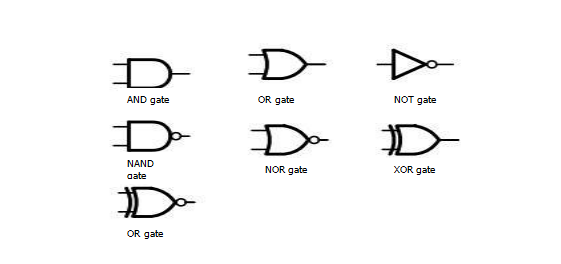

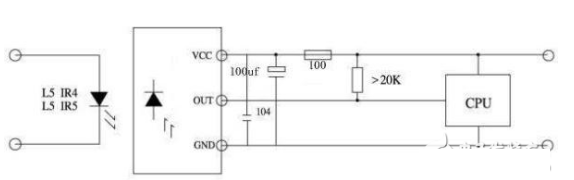

Passive devices can be used alone or in series or in parallel, for analog signal processing (RLC for amplification, attenuation, coupling, tuning and filtering), digital signal processing (pull-up resistors, pull-down resistors and impedance matching resistors), EMI Suppression (LC noise suppression) and power management (R for current detection and limiting, LC for energy accumulation) is an important part.

Limitations of discrete components

In the past, passive components were discrete, meaning that they were fabricated separately and connected in the circuit by wires or power rails on a printed circuit board (PCB). Over time, they evolved along three paths: smaller size, lower cost, and higher performance. These developments are now mature and optimized, but the footprint size and height dimensions mean that discrete passive components always limit the effort to reduce the size and size of the overall solution. Passive devices typically account for more than 80% of the bill of materials in an application, accounting for approximately 60% of the board area and approximately 20% of the total component expense. These factors combine to create very complex inventory control and storage challenges.

By its very nature, discrete devices are individually processed components. Although there may be ways to ensure that components are selected from certain process batches, each component is still highly unique. However, this is a significant disadvantage when a very matched component is required. For devices that need to be matched, the uniqueness and variability between components can cause errors, which can reduce the circuit performance at time zero. In addition, this performance degradation is always getting worse during the operating temperature range of the circuit and during its lifetime.

Another disadvantage of discrete passive components is that the assembly and routing of individual components is time consuming and takes up a lot of space.These components are connected using a soldering process and are typically assembled through via or surface mount packaging (SMT).Through-hole is an older assembly technique that inserts a leaded device into the hole in the PCB,any excess lead length will be bent and cut,and the device leads are connected to the PCB interconnect by wave soldering.rail.Surface-mount packages help achieve smaller passive components.In this case,the mounting connection pattern is etched on the PCB,the solder paste is overlaid on the pattern,and then the placement machine is used to position the SMT component.The PCB is then subjected to a reflow process (where the solder paste liquefies and establishes an electrical connection),and upon cooling,the solder paste solidifies and mechanically connects the SMT component to the PCB.The main problem with these two assembly techniques is that the welding process can be very unreliable,and this is becoming more and more worrying in industries where the target of defects is in parts per million.Several factors are important in ensuring solder joint reliability:the actual composition of the solder paste (now basically lead-free,so reliability is reduced),mechanical stability in the reflow process (mechanical vibration can make solder joints) Dry),the purity of the solder paste (any contaminants can have a negative impact on the reliability of the solder joint),as well as the time and temperature in the reflow process.The speed at which the solder paste is heated,the uniformity of the actual temperature and temperature,and the time the solder paste is heated are critical.Any of these changes can cause damage to the connection pads or vias,or it can cause mechanical stress on the device that can cause failures over time.

Another limitation of using passive components on the PCB is that the traces need to be long due to their distribution throughout the board.This may introduce parasitic parameters that are not counted,thereby limiting performance and result repeatability. Typically,PCB traces have a length and capacitance of approximately 1 nH/mm self-inductance,depending on the line width and distance from nearby traces.The tolerance of PCB traces leads to variations in parasitic parameters,so it not only brings parasitic damage,but they are still unpredictable.Shrinking tolerances on PCBs increases costs.

Passive devices also provide a number of potential contact points with the outside world that can be subject to ESD events through manual processing or machine processing.Again, this can have adverse effects and risks on overall reliability and robustness.

Advantages of integrated passive components

Before delving into the advantages of integrated passive devices compared to discrete passive devices,we first outline the origins of integrated passive devices.Integrated circuits now contain many transistors (in fact,millions) that are connected to each other by fine metals. For analog applications,the industry has also developed special processes such as DACs and ADCs that include passive components such as resistors and capacitors in addition to transistors.In order to achieve the performance required for these sophisticated analog applications,very high quality passive components have been developed.These high quality passive components are used to build integrated passive components.Just as integrated circuits contain many transistors,integrated passive devices can contain many high-quality passive components in a very small package. Like integrated circuits,integrated passive devices are fabricated on large-area substrates (wafers) while generating multiple passive networks.

One of the most compelling advantages of integrated passive components compared to discrete passive components is the ability to achieve precise matching.When manufacturing an integrated passive network,all components within the network are manufactured simultaneously under the same conditions,have the same material,and are basically in the same location due to the compact network. Passive components fabricated in this manner are more likely to have an excellent match than discrete passive components.To illustrate this,let's assume that there is an application that requires two matched resistors.These resistors are fabricated on a circular substrate such as a silicon wafer,as shown in Figure 1.Due to subtle process differences,such as the thickness of the resistive film,the chemical nature of the film,the contact resistance, etc.there will be a certain difference in resistance in the same batch,and the difference value will be larger in multiple batches. In the example shown in Fig.dark green indicates that the resistance is at the high end of the tolerance range,and yellow indicates that the resistance is at the low end of the tolerance range.For a standard discrete device,either of the two resistors may come from a different manufacturing lot, as shown by two separate resistors in red.The range of tolerances that can be observed between these two discrete resistors may be the tolerance of the entire process,so the matching is poor.For special ordering restrictions,it is possible to select the two discrete resistors from the same batch,as shown by the two separate resistors in blue.

The observable tolerance between these two resistors will only be the tolerance range within the same batch.Although the match between these two resistors will be better than in the case of random discrete devices,there may still be some degree of mismatch.

Finally,for integrated passive devices,the two resistors come from the same chip,as shown in Figure 1 black.The only observable tolerance between these two resistors is the tolerance range within the same die.Therefore,the match between these two resistors will be excellent.In addition,other techniques and other methods using a crossed quadrilateral layout can further severely limit the diffusion between the two resistors to achieve optimum matching of the components.Matching between integrated passive components is not only better at time zero than discrete passive components,but also maintains better matching over temperature,mechanical stress and lifetime over time due to their well-coupled manufacturing.recording.

Using integrated passive components in the micro-module SIP

The individual components in the integrated passive device are placed closely together (actually in the micron range),so interconnect parasitic parameters such as wiring resistance and inductance can be kept to an extremely low level.On the PCB,interconnect parasitics may change due to trace tolerances and component placement tolerances.Because of the lithography process used in the manufacturing process,interconnect tolerances and component placement tolerances using integrated passive components are small.In integrated passive devices,not only are the parasitic parameters very small,but these few parameters are predictable and therefore highly reliable.

The miniaturization of passive networks by integrating passive components brings the advantages of small size directly to the board.This directly reduces board cost and allows for more functionality and higher performance in a smaller footprint.When using integrated passive components,building a multi-channel system becomes more practical.

Another significant advantage of integrated passive components is the robustness around their entire wiring network.Integrated passive components are essentially forged together in a complete unit,sealed with glass,and then further protected by a robust plastic package without the need for extensive solder connections.In integrated passive networks,there is no problem with solder joint drying,corrosion or component misalignment.

Another advantage of the excellent performance of the integrated passive network seal is that the number of exposed nodes in the system is greatly reduced. As a result, the likelihood of system damage due to accidental short circuits or electrostatic discharge (ESD) events is significantly reduced.

Maintaining and controlling the inventory of components assembled on any board is a very complex task.Integrated passive components contain multiple passive components in a single device,greatly reducing the customer's bill of materials burden and reducing the cost of ownership.Customers get fully tested and fully validated integrated passive networks.This means that the output of the final board construction is improved,which not only saves further costs,but also improves the predictability of the supply chain.

Use ADI's Integrated Passives (iPassives)

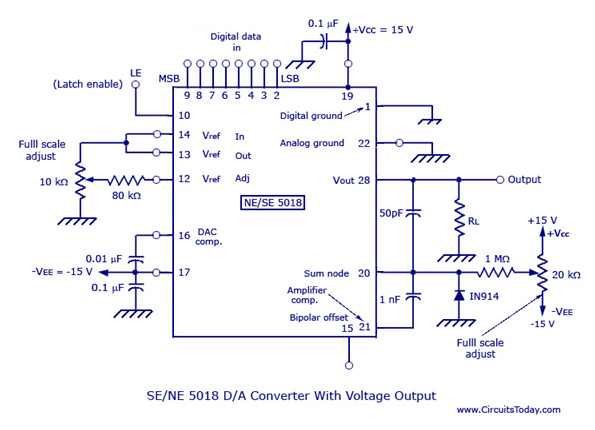

As mentioned earlier,high-quality passive components have been at the heart of the circuit performance that ADI has achieved over many years.During this time,the range of passive components continues to expand and quality continues to improve,and the integrated passive device portfolio now includes a large number of components.The integrated passive device uses a modular process,which means that the process steps required to produce a certain type of passive device need to be performed only when specific components are required.The construction of the iPassives network basically requires only the necessary process complexity,no more and no less.As shown in Figure 2,there are many passive building blocks to choose from,and building an integrated passive network is as simple as assembling the required components together.

Using integrated passive components in the micro-module SIP

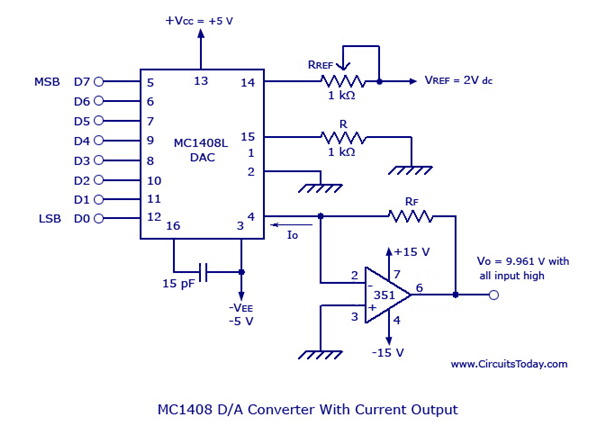

As mentioned earlier in this article, integrated passive devices have many advantages over discrete passive devices. ADI has further enhanced these advantages by using them in μModule devices. These modules take advantage of the capabilities of various integrated circuits. These circuits are manufactured through a tailor-made process that provides enhanced performance that cannot be achieved by any other single process. ADI is using iPassives to connect these integrated circuits together to build a complete precision signal chain in a single device. The two μModule device examples in Figure 3 include data converters, amplifiers, and other components that are combined by a passive gain and filter network built with integrated passive components.

Using integrated passive components in the micro-module SIP

ADI produces highly customizable precision signal conditioning systems.Using a reusable approach from a large portfolio of field-proven IC products and combining it with the versatility of iPassives,the development cycle time and cost are significantly reduced. This decision provides customers with a huge advantage,allowing customers to use their most advanced performance to get to market faster and more efficiently.

in conclusion

At first glance,using integrated passive devices may only be slightly more advantageous than other more mature methods. However,the practical advantages are even more pronounced.ADI's adoption of iPassives not only redefines the achievable functions,but also redefines speed,cost and design size to make it more beneficial to customers.